New efficiencies with advanced solutions

No matter if you call it hazardous locations, Ex areas, classified areas, explosive areas or hazardous areas, they all carry increased risks of explosions and have strict regulatory requirements pertaining to the protection method of electrical equipment. Different explosion-protection techniques are permitted within the various zones and divisions. Axis explosion-protected products optimized for these allow you to choose technology that goes far beyond surveillance to provide added value to your business, not only optimizing safety but also the efficiency of your production.

Hazardous areas eBook

Learn more about how our explosion-protected products can bring value to your operations.

Optimize safety, production and security

Axis explosion-protected products are designed to run multiple tasks. The same camera that monitors for overall plant welfare can also support existing safety and security protocols. These multitasking capabilities mean more flexibility in deployment of fewer cameras, ensuring a cost-effective investment. Adding network audio further enhances that value.

- Health and safety – add a layer of safety and minimize unnecessary human exposure to hazardous areas

- Operational efficiency – increase efficiency and maximize uptime

- Security - secure areas to prevent sabotage and theft

Focus areas

Health and safety - minimize human exposure

Our solutions open up a range of options to help staff on site stay safe. You can use them to monitor worker activities in real-time, send live or pre-recorded audio messages, or take advantage of automated safety functions through intelligent analytics. Our explosion-protected products provide situational awareness and will also help maintain safer working conditions and processes. Rather than replacing people, our products can be an effective way to minimize unnecessary human exposure to hazardous areas.

Examples of use cases

1. Enable fire prevention with early detection of smoke and fire

2. Use personal protective equipment (PPE) detection for safety equipment alerts

3. Monitor confined spaces and restricted areas to minimize staff exposure to high-risk situations

Operational efficiency – maximize uptime

Disrupted production and downtime is costly, no matter what causes it. By integrating Axis explosion-protected products with your control system architecture, you add another level of transparency to help you understand more of what is happening with your operations. By enabling more and better data collection, Axis and partner technologies can help predict maintenance and alert you when anomalies and other disruptions are detected.

Examples of use cases

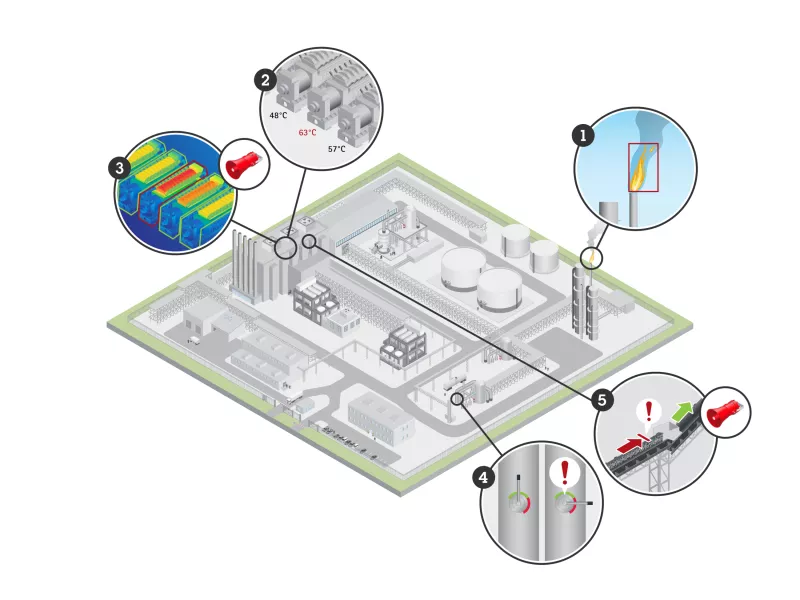

1. Monitor flares, giving you oversight of waste gas disposal and an ongoing indication of overall plant performance

2. Gain greater scene understanding through data overlays

3. Monitor equipment overheating, and temperature changes, enabling predictive maintenance

4. Use visual verification of incident alerts to avoid process or plant shutdowns, or unnecessary service personnel deployment

5. Automatically detect anomalies in production to quickly remedy potential issues

Security - prevent sabotage and theft

Axis explosion-protected products help you protect operations through the prevention of sabotage and theft. By integrating our cameras with network audio, you can deter unwanted activity with live or pre-recorded audio messages that let suspects know they have been detected.

Examples of use cases

1. Avoid sabotage to ensure the integrity of the product and that production is up and running

2. Mitigate theft to safeguard raw material and finished goods

Products for every need

Axis broad portfolio consists not only of Zone/Division 1 products, but also of a camera specifically designed and certified for Zone/Division 2, all rigorously tested and approved.

Solutions for safe areas

Intrusion, interruption, injury. These are the main threats to productivity, profitability, and employee safety in any industrial operation, from manufacturing, all the way to critical infrastructure processes and deliveries. In safe areas, not classified as hazardous, Axis smart solutions address all three of these areas, comprehensively and cost-effectively. Our products – including connected thermal and visual cameras, radar devices, access control, and audio equipment – can be combined with innovative analytics software, to help you handle assets and operations with more security, safety, and efficiency.